Sider GATES

TUNDISH SLIDING

GATES

Tundish slide gate systems

for billet and bloom casters

Controlling the flow of steel from the tundish to the mould is very important for Bloom and Billet Casters with flow control valve.

It strongly contributes to the ability to produce the optimum steel quality with the maximum caster safety.

ADVANTAGES

- Precise flow control

- Longer casting sequence at continuous caster

- Easy handling due to the compact design

- Automatic casting startup

- Automatic bath level control in the mould

- Visualization of the casting process

CONCEPT

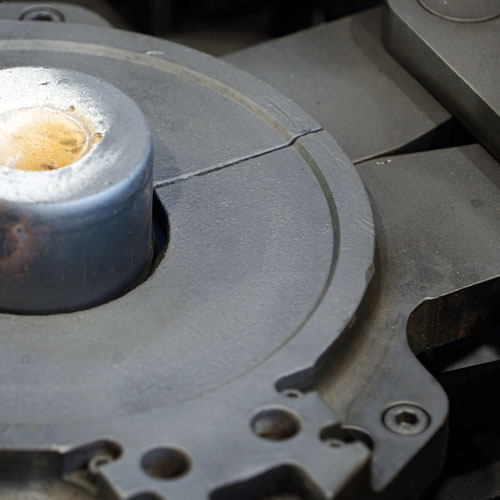

Our “TM” tundish gate is provided with 3 plates in order to avoid the movement of the subentry shroud in the mould during the flow control by throttling.

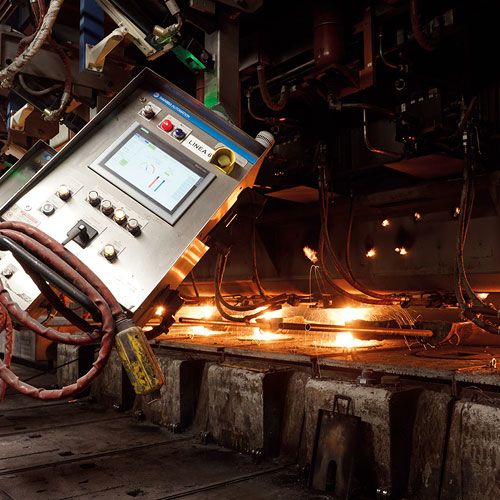

MOLD LEVEL CONTROL CABINET

- Three plate gate system (bore size 35mm or 40mm)

- Designed for fully automatic casting operation

- Direct connection between submerged nozzle and lower plate

- Inert gas application on tundish nozzle and joints

- Air tight system concept supported by argon bath principle

SCOPE OF SUPPLY

- Mould Level Control Cabinet

- Visualization and Process control

- Mould Level Measuring System

- Operator Panel and Control Boxes

- Tundish Slide Gate mechanism

- Hydraulic power unit

- Hydraulic components on tundish car

- Accessories for preparation area

ASSEMBLY AND DESIGN

- Easy assembly and maintenance, designed to minimize the number of components, either on-line or off-line

- Fastening with bolts

- Easy detachable hydraulic cylinders

- Hydraulic cylinders are installed on the tundish car and are easily disconnected form the gate

- All hydraulic circuits are closed-loop

- Separate preheating of submerged nozzle

- High safety standard for operators and CCM

ADVANTAGES

The CRB series of quick nozzle changers offer a state-of-theart technology engineered to suit all casting requirements in terms of:

- Extend casting sequence

- Extend tundish lining life

- Maintain tundish level for maximum quality

- Re-start at desired speed

- Change nozzles on individual strands

- Emergency blanking and later re-start

- All refractories are installed inside the mechanism

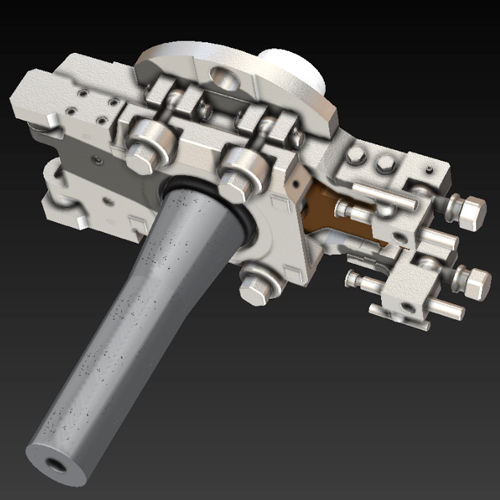

LOW WEIGHT / HIGH STRENGTH

The net weight of the gate assembled with the refractories is only 19.5 kg. The frame design and the material guarantee high stiffness and strength properties.

CRB 08.2

Two main structural parts that clamp the spring pads and the refractories. Double opening hinge. Blind nozzle must be inserted in the stand-by position after nozzle changing procedure.

CRB 09 SERIES

One main structure, interchangeable with the one of Q3 slide gates. Spring pads are bolted to the main structure Blind nozzle is always available in the emergency position for extra safety

SAFE OPERATION

In order to strongly increase the operational safety the system has:

- Two, independent, spring pads for each rocker

- Mechanical devices that prevent wrong operation of the cylinder.

- High coaxial precision while changing the refractory nozzle.

- Upper nozzle with round section and flying nozzle with square section inscribed inside the upper nozzle to maximize surface contact.

- The preparation/testing table, during the refractories preparation, allows to check the springs though a load digital cell without further auxiliary operations.

This provides:

- Strong increased operational safety.

- Fast and frequent springs control.

- Reduced non-operational times (it is no necessary disassemble the springs for the main structure).

ADVANTAGES

The Q3 sliding gate series is a compact 3-plates linear mechanism for dynamic flow control, expecially designed to meet all the requirements in closed casting conditions on tundish casting machines.

The system features consists of:

- Lower refractory cost compared to existing system on market*

- Fully automatic dynamic flow regulation operation

- Direct connection between submerged nozzle and lower plate

- Inert gas application on tundish nozzle and joints

- Air tight system concept supported by argon bath principle

- Optimized number of components

CONCEPT

Our Q3 tundish gate is provided with 3 plates in order to avoid the movement of the subentry shroud in the mould during the flow control by throttling.

FEATURES

All hydraulic circuits are closed-loop for trouble-free casting.

Fastened with bolts on tundish bottom.

SCOPE OF SUPPLY

- Mould Level Control Cabinet

- Visualization and Process control

- Mould Level Measuring System

- Operator Panel and Control Boxes

- Tundish Slide Gate mechanism

- Hydraulic power unit

- Hydraulic components on tundish car

- Accessories for preparation area

DESIGN

The Q3 system is an easy-maintenance tundish flow control gate suitable for bore sizes up to Ø40mm.

- The design ensures a fast and safe installation

- Reduced number of components

- Cylinders directly installed on tundish car

- Easy detachment from the gate

- Separate preheating of the submerged nozzle

- Respect high safety standards for operators and CCM

- Dedicated mould level control unit

CONNECT WITH US FOR SUPPORT OR ANY QUESTION!

CONTACT FORM

+39 030 7002350

SUPPORT

for our Customers